|

| Focus | Highlights | Research Grants | Awards | Facilities| Careers |

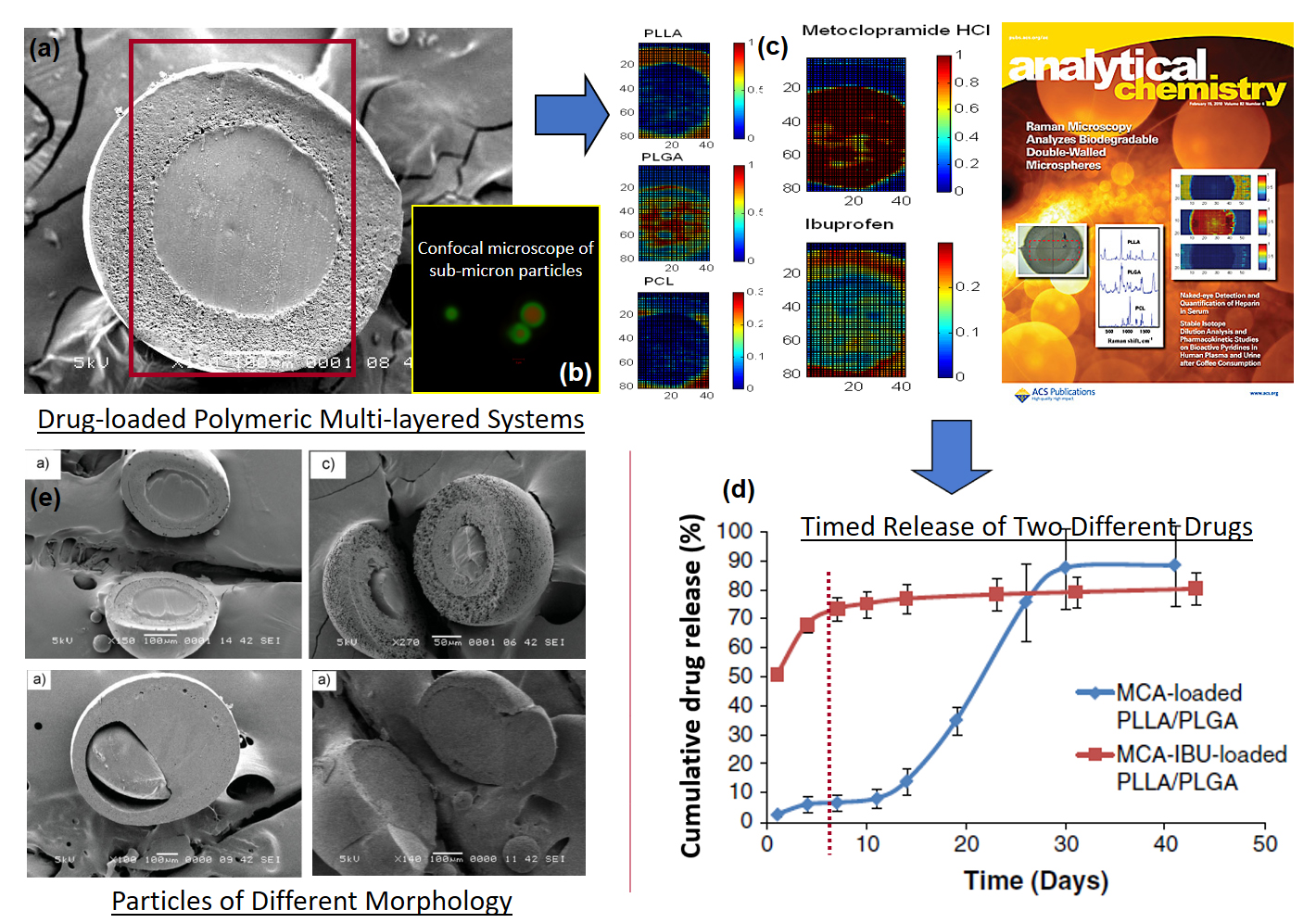

Multi-layered Particulate SystemsThrough a one-pot synthesis technique, double-layered, triple-layered and quad-layered microparticles can be fabricated with alteration to its particle configuration, i.e. layer thickness and particle size. Therapeutic agents of different properties may be selectively localized in the different polymer layers of these particles through drug-polymer interaction. Moreover, drugs in different layer can be customized for controlled release at a timely manner thus giving its unique drug release profile and kinetics. With this invention, we demonstrated how this distinctive structure of multi-layered microparticles can modulate the release profiles of anticancer drugs, and how co-delivery can potentially provide better antitumor response. Besides that, another double-layer microparticles provided an earlier and sustained dose of therapeutic drug to the wound and reduced the oxidative wound microenvironment to accelerate healing, in contrast to single-layered microparticles Patent: CN 102458640 A/B, EP 2437879 A1/A4/B1, US 20120128752 A1, US 20120128752 A1, WO 2010140987 A1 |

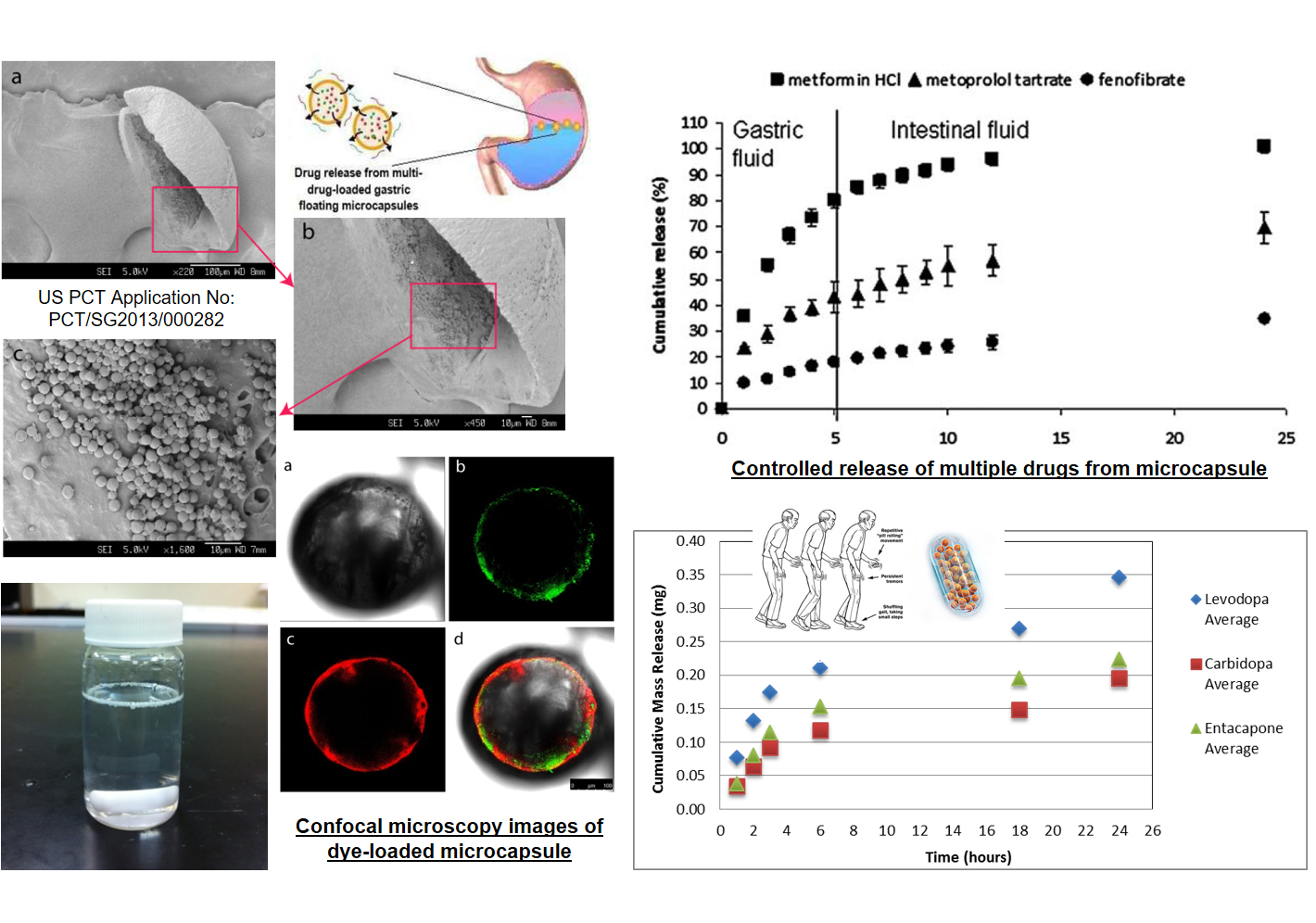

Floatable Multi-drug-loaded CapsulesBusy schedules, several different types and frequencies of oral medications often causes many patients to fall behind on medications and resulting in skipped doses which may hamper their recovery. Our group developed a floating polymeric microcapsule that can simultaneously house different drug-loaded particles and releasing them in a controlled and timely manner. Its excellent buoyancy and prolonged gastric residence time in stimulated gastric acid with sustainable release capability allows a sustainable availability of multiple drugs in the body for up to 24 h. This invention presented us a potential once-a-day poly-pharmacy pill that demonstrated similar or even better effect in term of convenience and treatment efficiency than the traditionally consumption of numerous pills by the patients. Patent: US 9381163 B2, US 20150164815 A1, WO 2014027956 A1. |

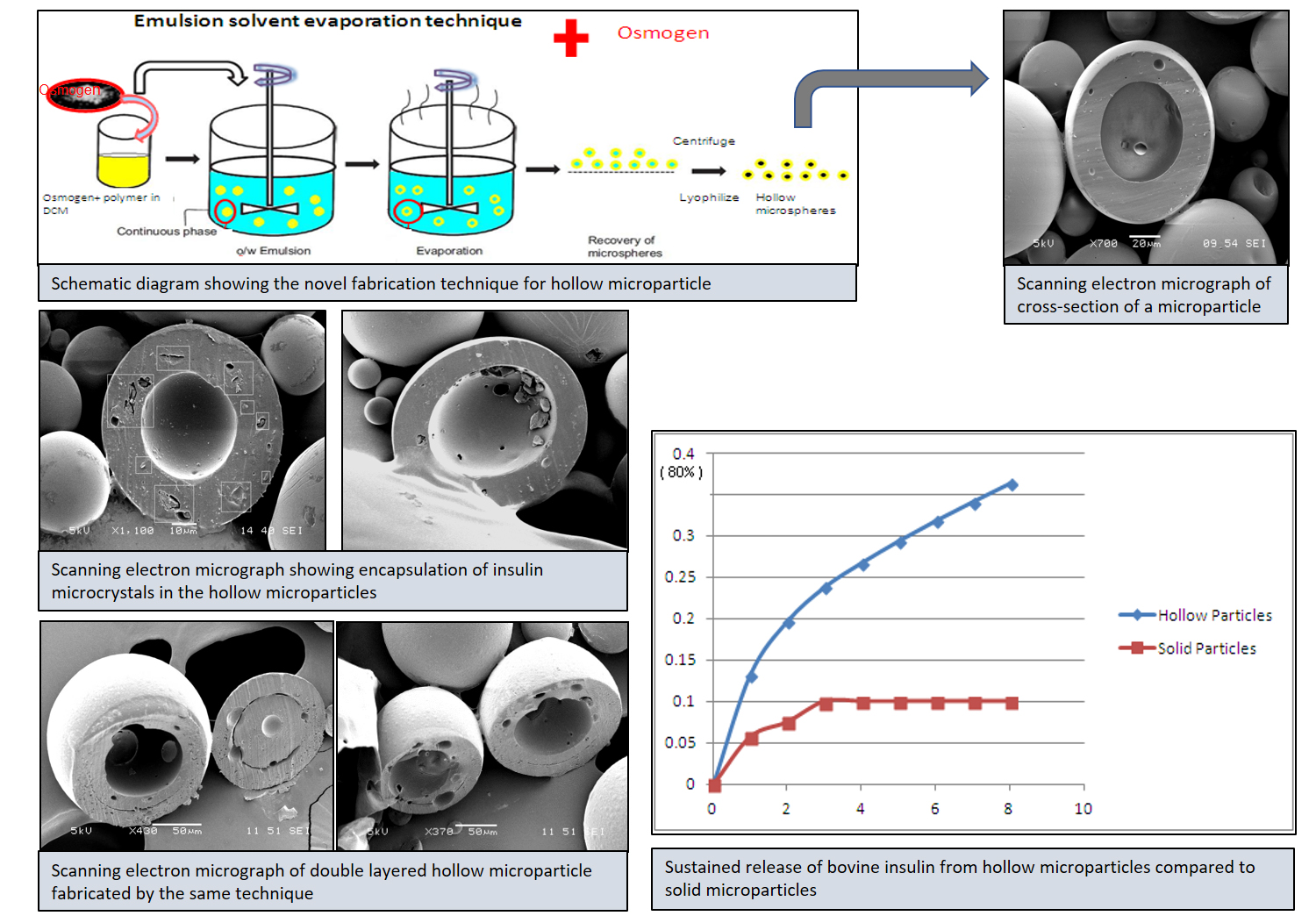

Osmogen-mediated Hollow ParticlesMicro particulate systems composed of biodegradable polymers, such as poly(d,l-lactic-co-glycolic acid) (PLGA), are widely used for controlled release of bioactive molecules but their acidic degraded by-products often perturbs the configuration of most encapsulated proteins and lead to an unrealistically slow and incomplete release of proteins. To address these drawbacks, hollow PLGA microparticles were fabricated through a novel one-step oil-in-water emulsion solvent evaporation technique, by capitalizing on the osmotic property of an osmogen. Our studies showed that the bioactivity of bovine insulin microcrystals loaded within these hollow microparticles are maintained and their release profiles can be fine tuned by manipulating with the osmogene concentration. Patent: WO 2016089309 A1 |

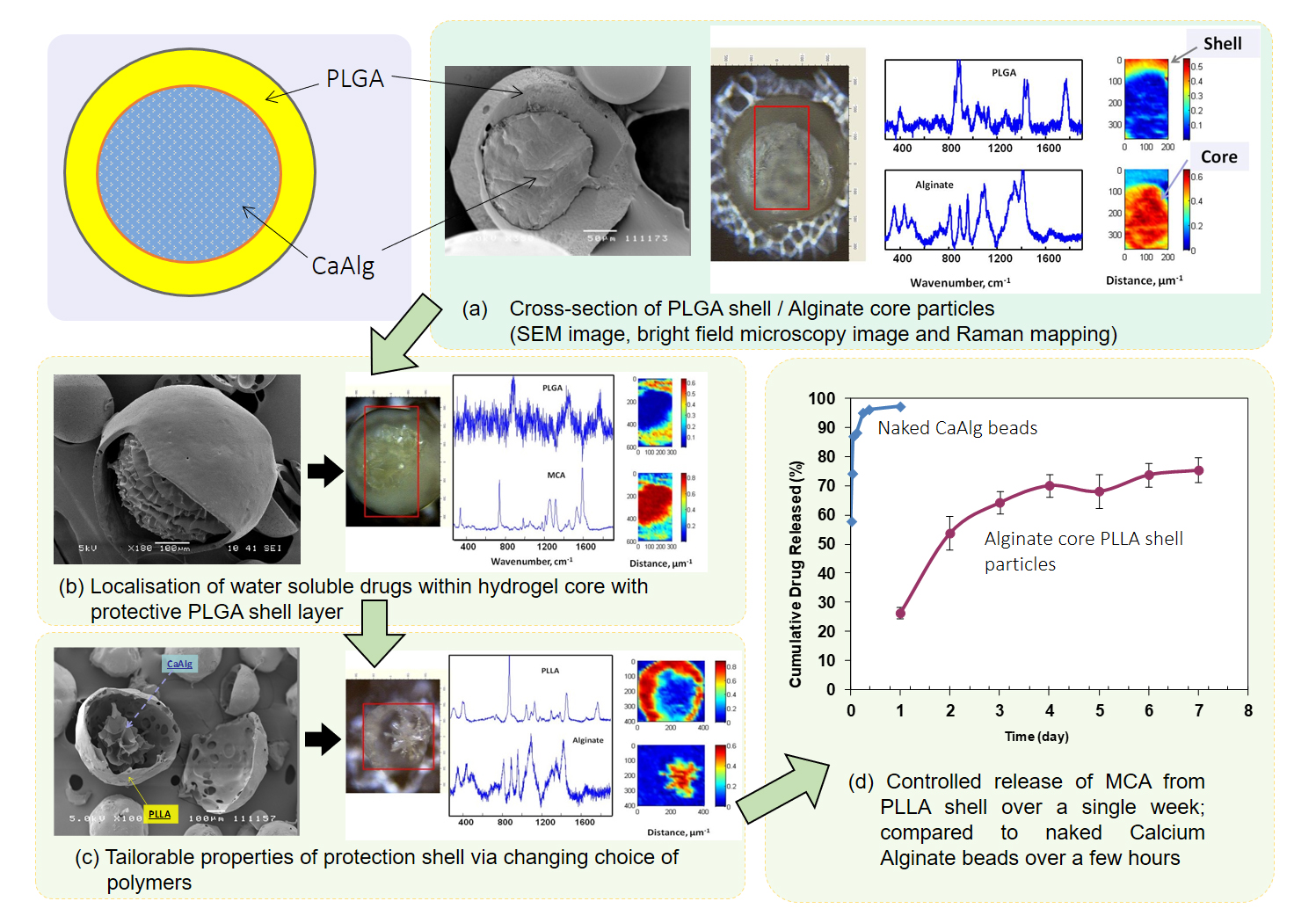

Hydrophilic-Hydrophobic Core-Shell ParticlesCurrent focus on particulate drug delivery entails the need for increased drug loading and sustained release of water soluble drugs. Commonly studied biodegradable polyesters, such as poly(lactide-co-glycolide) (PLGA) and poly(L-lactide) (PLLA), are lacking in terms of loading efficiency and a stable encapsulation environment for proteins. While hydrogels could enable higher loading of hydrophilic agents, they have inferior controlled and sustained release profile. The solution to this issue is the development of microparticles with a hydrophilic drug-loaded hydrogel core (e.g. alginate) for improving hydrophilic drug loading, encapsulated within a biodegradable polyester shell (e.g. PLGA, PLLA) for controlled and sustained release. We follow a one-pot strategy for fabricating such microparticles via a concurrent ionotropic gelation and solvent extraction. In one of our study, the core alginate has demonstrated increased encapsulation efficiency of a hydrophilic drug, metoclopramide HCl (MCA) while the PLGA or PLLA shell control the release of drugs. This gel-core hydrophobic-shell microparticles thus allows for improved loading and release of water soluble drugs and find its vital applications in protein therapeutics. Patent: WO 2013119183 A1 |

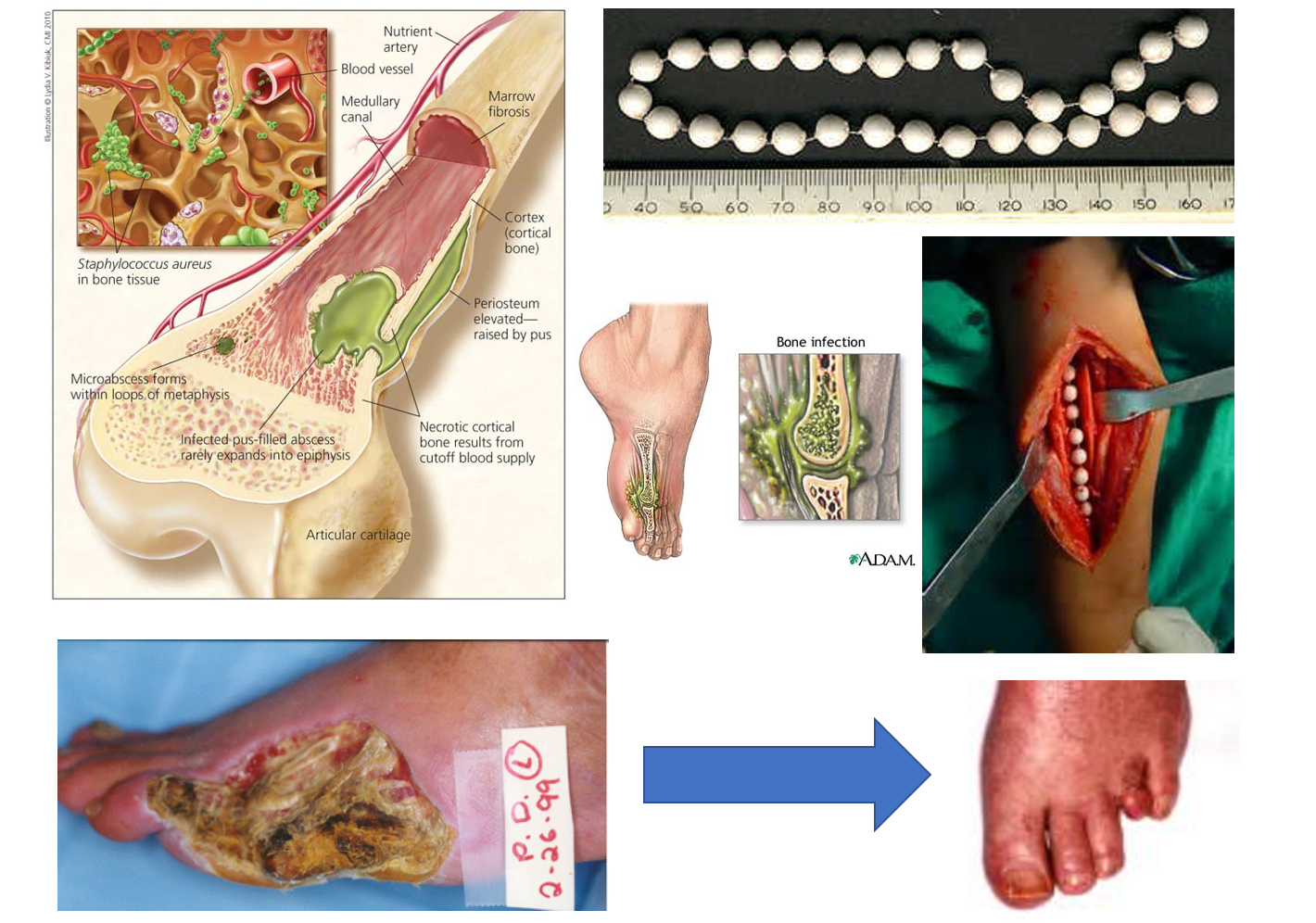

Bone-targeting Drug Delivery SystemsOsteomyelitis or bone infection is one of the most difficult complications in orthopaedics due to its poor blood circulation around the infected bone. We develop a particulate system that not only sustains the drug release up to 4-6 weeks to eradicate the infection, but also possesses bone mimicking properties to facilitate bone regeneration. This was achieved by fabricating carrier system comprising of a polymeric core and calcium phosphate (CaP) ceramic coating through a surface adsorption-nucleation technique. The presence of CaP coating helps to reduced burst release of drugs significantly especially in the case of hydrophilic drug. These particles also demonstrated their capability to inhibit bacteria growth and deteriorate biofilm up to 4 weeks. Furthermore, surface modification of the particles by bone-targeting ligand, bisphosphonate (BP) helps further to facilitate targeted drug delivery and localization to the bone site. Patent: CN 102574879 A/B, European patent EP 2438076 A1/A4, United States patent US 8933058 B2, US 20120142641 A1, World patent WO 2010140986 A1 |

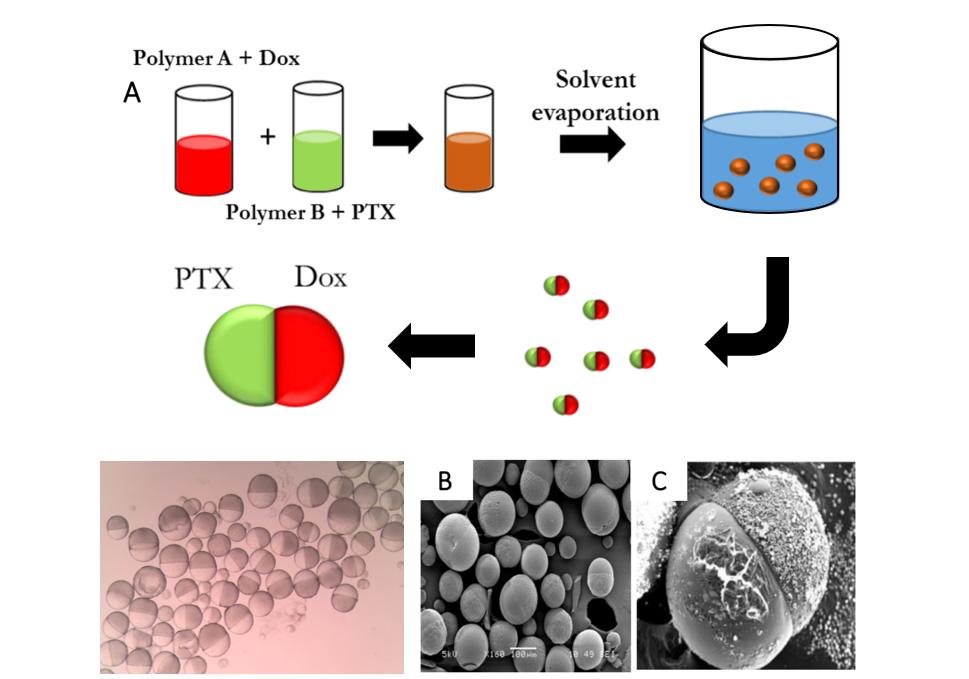

Janus Particles through One-stepJanus Particles comprise of two compartments which carry the advantage to load each with different agent. Conventional multi-step techniques are usually tedious and hence our group developed a single-step methodology to increase the production of Janus particles. One potential use of these Janus particles includes target localized delivery of therapeutic agents. For instance, encapsulation of superparamagnetic iron oxides within one polymer face allow targeted localization under the control of a magnetic field while releasing the drugs on the other polymer face. The theranostic potential of these particles is also been currently explored. |

Updated on 10 January 2018 | Copyright @ Delivery and Controlled Released Technologies Laboratory, School of Materials Science and Engineering, Nanyang Technological University |