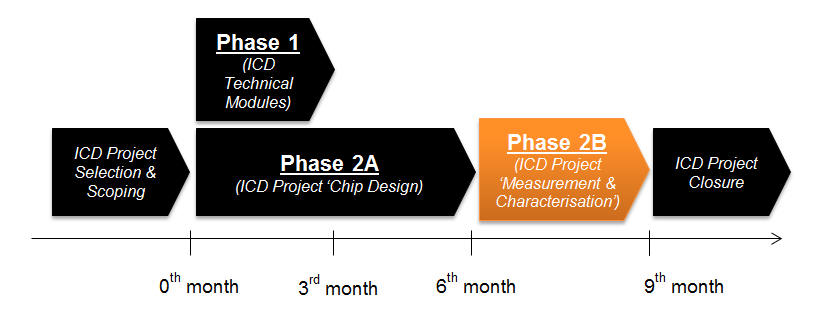

Phase

2B – Integrated Circuit Design Project ‘Measurement &

Characterisation’

Key Deliverables – Yield

enhancement & Design improvement

Duration: 3 months

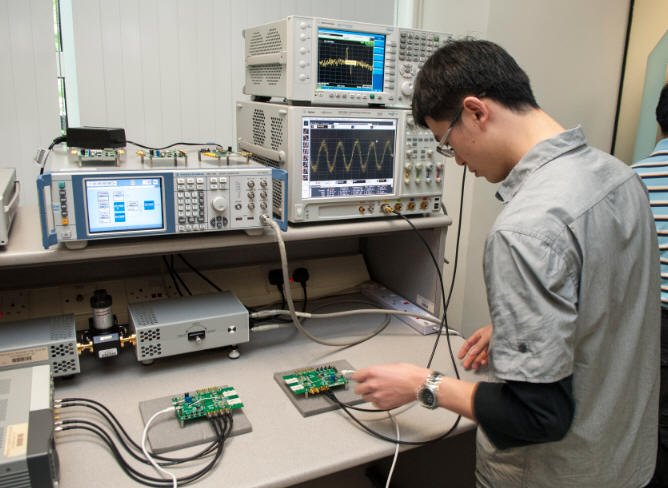

(i) A good post-layout simulation result does not necessarily

warrant a successful product. In reality, the actual performance

of the IC can only be ascertained by carrying out measurement

and testing of the IC hardware returning from the fabrication

facility. In the measurement and testing step, the fabricated IC

prototype or the packaged IC is subject to rigorous electrical

and functional measurement and testing on top of specification

checks. If the measurement result is not on-target, the

designers need to perform troubleshooting or debugging of the IC

to identify potential technical flaws. All design specifications

must be met before proceeding to the packaging.

(ii) In order to ascertain if the IC meets the electrical

specifications, state-of-the-art equipment such as 12” probe

station, semiconductor parameter analysers, precision LCR

meters, network analysers, high frequency noise parameter

systems, load-pull systems, 1/f noise systems, jitter/bit error

rate testers, function generators and oscilloscopes are needed

to perform the necessary measurements.

(iii) Some ICs may have to be mounted on printed circuit boards

for additional testing.