|

Current Funded Research Projects and Collaboration |

Nano Membrane

Water and Energy Research

|

| |

19. Conversion of CO2

into CH4

Using HOT-DNA Membrane (2013)

Newly developed two-dimension (2D) HOT-DNA membranes brought

in new properties such as flexibility, multifunctional

while retaining its 1D properties such as not only UV but

Vis light application.

This proposal is to develop an integrated cost

effective CH4

production

from

CO2.

The focus of our proposal is to fabricate and assemble

heterojunctioned HOT-DNA UF

membranes

and its modules for cost effective CH4

production from CO2

through the study of the flexibility mechanisms of

heterojunctioned

HOT-DNA membrane and the fundamental intersections of

heterojunctioned HOT-DNA membrane and its

biological, chemical, physical, atomic physical and quantum

activities. Furthermore in a nano-solid state, the

fundamentals

of the interaction of HOT-DNA membranes and light will be

studied in the context of cavity quantum effect

diffusion.The objective

of this project is to develop a HOT-DNA membrane reactor for

converting CO2

into CH4

under

solar condition. |

|

|

18.

Multifuncational Nanostructured Membrane for Clean Water and

Energy Production (2012)

The objective

of this project is to develop a novel nanofibe/wire/tube

membrane with multifuctional properties

such as anti-fouling, concurrent

water purification and energy production. |

|

|

17.

SPICE --Singapore Process Integration Centre of

Excellence--with demonstration in

Singapore Refining Corporation Pte

Ltd. (Jan 2012)

This project is

to develop and demonstrate the local competence and

technology in the field of

industrial process integration

for optimized solution for increased water, energy and

production

efficiency in refining and

petrochemical process by setting up lasting competence

centre to service

the Singapore industry. This

project is supported by national Research Foundation

(NRF)/EWI. |

|

|

16.

Derived Bunker Fuel

from Waste Oil Sludge (Feb 2012)

This

proposal focuses on the new development trend using the

latest technology to convert the oil

sludge

regenerated from oil tank cleaning process into consumable

bunker fuels.

This project is

supported by MPA. |

| |

15.

E4.3--Couple AdvancedOxidation

Process (AOP): Sonophotocatalysis for Treatment of

Environmental Contaminants in RO Retenate Water,

NSF, USA

(2011)

The proposed project is to develop a nano

structured photocatalyst to remove the contaminants in

RO retenate water. The project is

supported by NSF, USA and collaborating with Stanford

University.

|

| |

14.

Nano composite

materials

for spilled oil recovery

(2011)

The proposed project is to develop a nano

composite materials with high adsorption capacity and

easy for spilled oil recovery,

dissolved oil and water separation and filtration.

|

|

|

13. Feasibility Study of Integrating Flexible Dye

Sensitized Solar Cells (DSSC) into Flexible

Sheets for UAV applications (Nov 2009)

This project is

to

fabricate the flexible DSSC using nanostructured flexible

TiO2

technology and to

utilize the special characteristics of

flexible DSSC to provide electrical power as a solar sheet

module.

This project is supported by TDSI. |

|

|

|

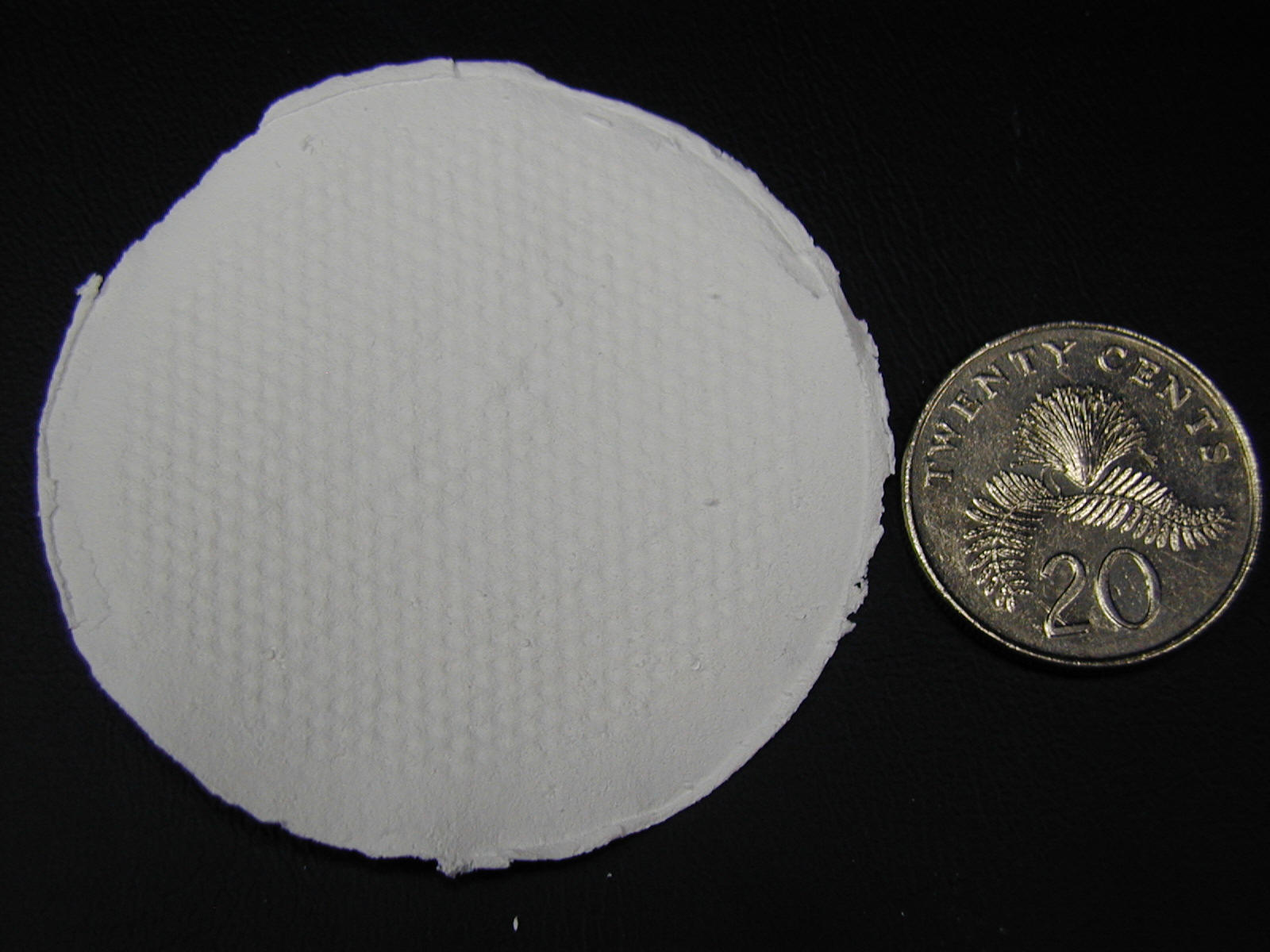

12. Assembling of Multifunctional TiO2

Nanofiber Membrane for Water Treatment (Dec 08)

The

cost for water reclamation is limited by a fouling problem

which is caused by the deposition of the

foulants

on membrane surface such as nature organic matters (NOMs)

and bacteria etc. This project is

to

create a concurrent photocatalytic oxidation (PCO) and

filtration membrane for large scale water

treatment

(self generation membrane). Due to the nanosized crystallite

(QUANTUM efficiency) of

TiO2 fiber, the PCO and filtration capability of

nanofiber filter are being improved significantly. The

membrane fouling problem will be minimized/disappear

(possible). Thus the proposed project is to

overcome the fouling problem of polymeric membrane and come

up with robust and free standing TiO2

nanfiber membrane for concurrent PCO and filtration. This

project is supported by National Research

Foundation

(NRF)/EWI. |

| |

|

11.

Development of flexible DSSC for Commercial Application

(Dec 08)

Low cost

fabrication and device stability are two main factors that

hamper the commercialization of the

dye sensitized solar cells (DSSCs). This project aims

to solve these problems by fabricating flexible

DSSCs. During the project, several new areas will be

explored, which include the fabrication protocols

for TiO2 fiber/tube/membrane, new concept of dye

sensitizers, and new strategies for device

fabrication. This

project is supported by National Research

Foundation (NRF)/Clean Energy Research

Program

(CERP). |

| |

|

10.

Concurrent Hydrogen

Production and Water Purification Using TiO2

Nanofiber/Microsphere |

| |

|

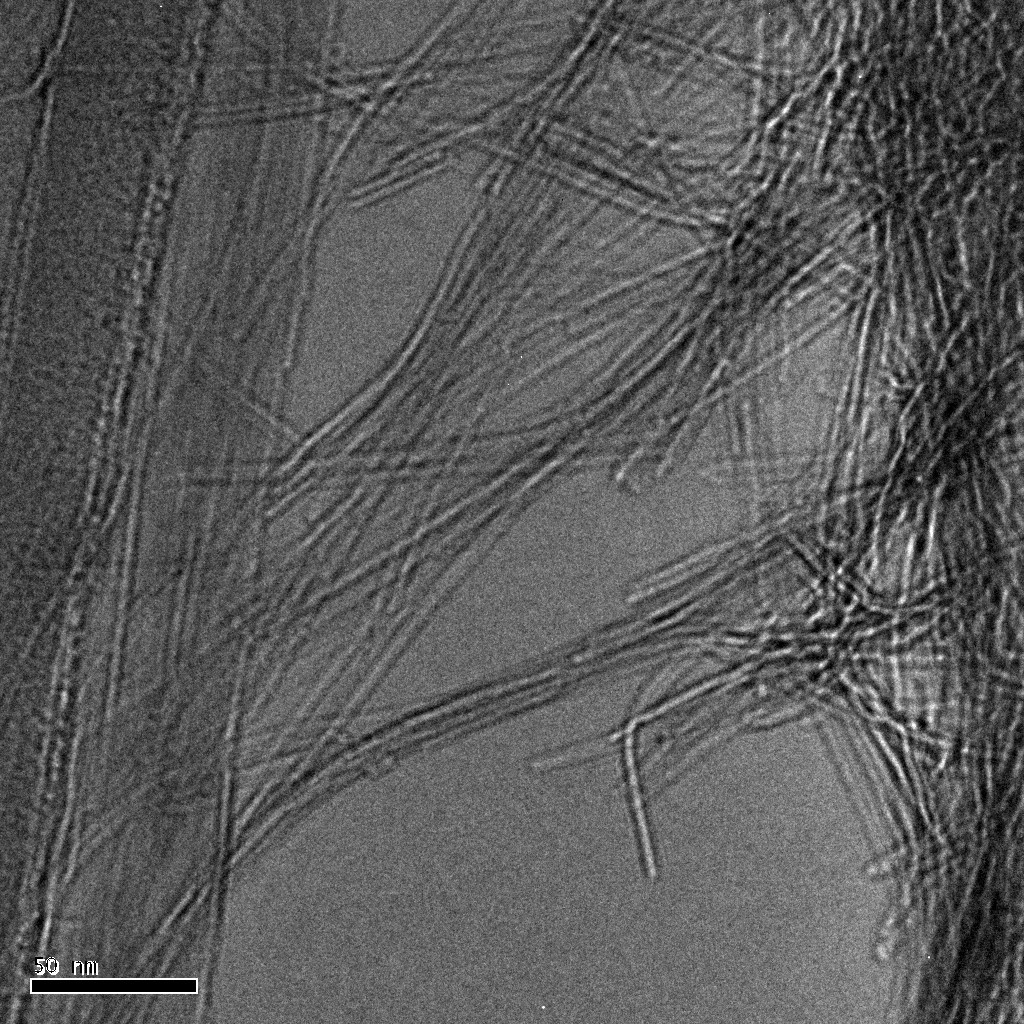

9.

TiO2

Nanofiber Membrane

for Removal of

Marine Microorganisms (Dec 2008)

The robust and

free-standing multifunctional ultrathin TiO2

nanofiber membrane acts as both filtration

membrane and photocatalyst in water technologies. In the

presence of ultraviolet light, the crystalline

TiO2 nanofiber is known to produce strong oxidant

and exhibit quantum size effects. These unique

properties give rise to various applications particularly in

(1) removing marine microorganisms from

water, (2) producing cost effective commercial filtration

membranes that could dramatically reduce

the cost of water production and (3) treatment of Ballast

water for safe discharge. This

project is

supported

by Maritime and Port Authority of Singapore.

|

|

|

8.

TiO2

Nanofiber/tube/microsphere Membrane Solar Cell (Oct 2008)

This project aims

to fabricate dye sensitized solar cells (DSSCs) for

maritime and port application

using TiO2

technology. This

project is supported by Maritime and Port Authority of

Singapore.

|

| |

|

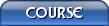

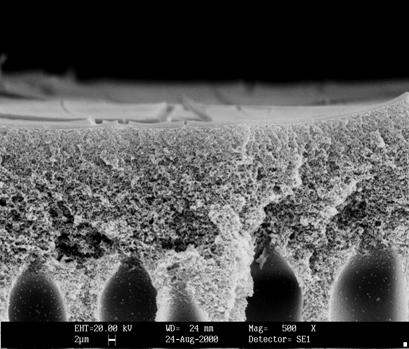

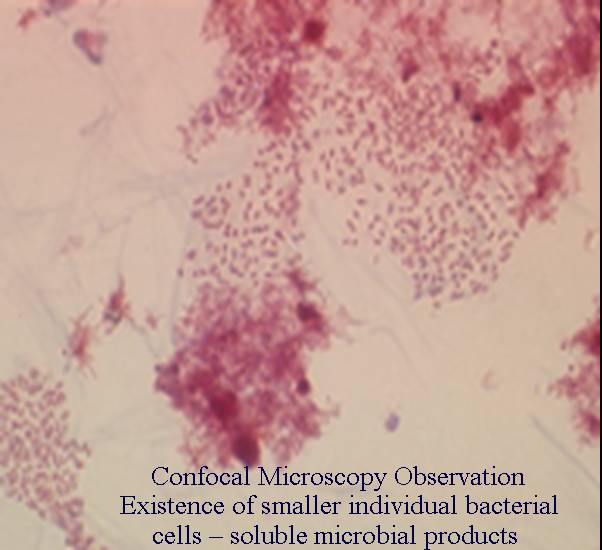

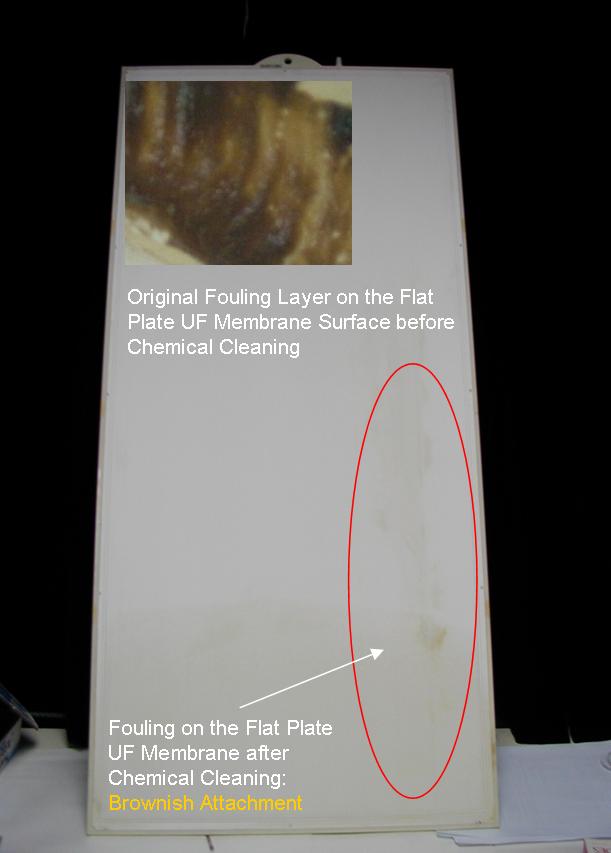

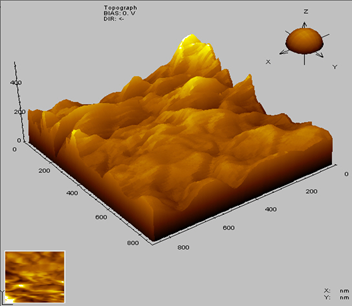

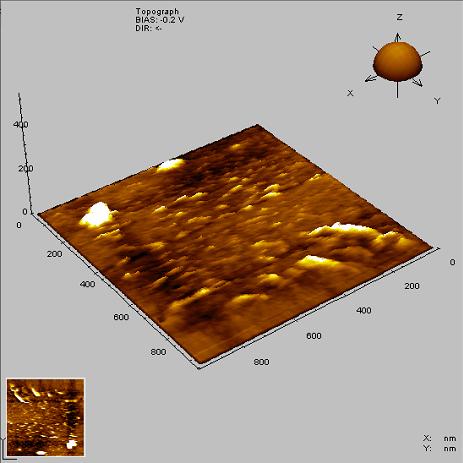

7.

Illustration Fouling Mechanism of Ultrafiltration Membrane

in Water Treatment Systems

|

|

NOM Fouling on UF Membrane Clean UF Membrane

Cross-flow Membrane Fouling Test System |

|

|

|

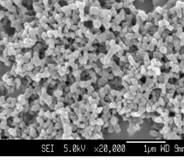

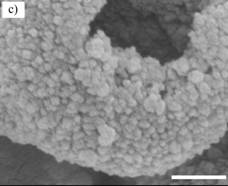

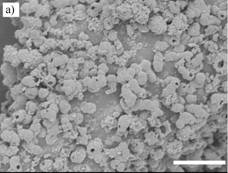

6. Nanostructured, Nanofiber/tube, Hollow Mesoporous

Microsphere & Its Membrane

Collaborators:

Stanford University

and

PUB

Nano-structured TiO2 microsphere photocatalyst Nanostructured hollow TiO2 microsphere

photocatalyst

|

|

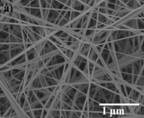

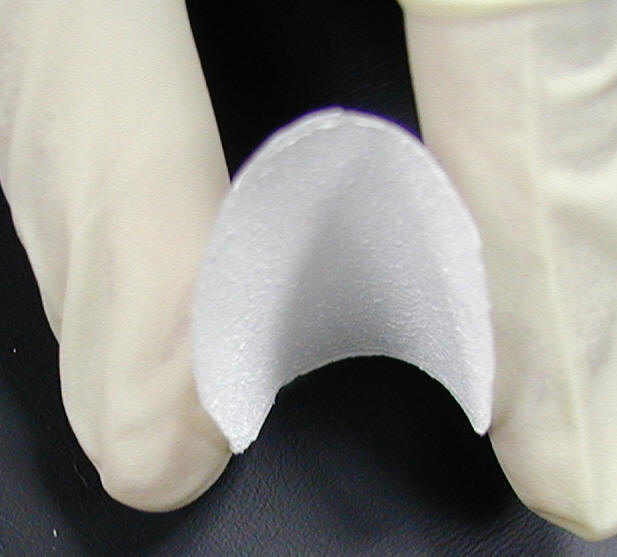

TiO2

nanofiber and TiO2

nanotube Free-standing

& flexible pure TiO2

nanofiber membrane |

| |

|

5. Nano-structured Photocatalyst for Membrane Fouling Control

Collaborators:

Stanford University

and

PUB

TEC Award from Prime

Minister's Office, Singapore

Click Here for News Release

|

|

TiO2 Nanostructured

Photocatalytic Microsphere for Membrane Fouling Control

(above)

TiO2 Microsphere and Membrane Water Treatment System: A Pilot

plant at CCK Waterworks Singapore (below)

|

|

4.

Filtration Membrane Fouling Mechanism and Control

|

|

|

|

3. Anammox

Membrane Bioreactor and

Membrane Biodigestor

for

Water Reclamation

Collaborators:

Stanford University

and

PUB |

| |

|

|

|

|

| |

Aerobic MBR has been used

since 1999 |

|

This MBR system consists of 3 sections by baffles,

the COD removal, the anoxic N removal and the membrane filtration |

|

| |

|

|

|

|

| |

|

|

|

|

| |

Aerobic membrane biodigestor (MBD) |

|

Anammox membrane bioreactor |

|

|

|

|

|

2. Nanofiltration Membrane for Water Reclamation |

The

manufacturing of semiconductor integrated circuit (IC) chips

with indium phosphide (InP) produces

toxic wastewater that

requires proper treatment prior to safe discharge. In this

work, a few nanofiltration

(NF) membranes were applied to

the separation of both suspended InP particles and dissolved

indium

(In3+) from the wastewater. This

study focused on (a) the performance of such a NF

process under

various operating conditions;

(b) effects of

electrochemical potential of indium, as a multivalent cation,

on

nanofiltration;

(c) colloidal fouling of the membranes and

the associated impacts on nanofiltration, and (d)

modeling of nanofiltration processes.

|

|

|

|

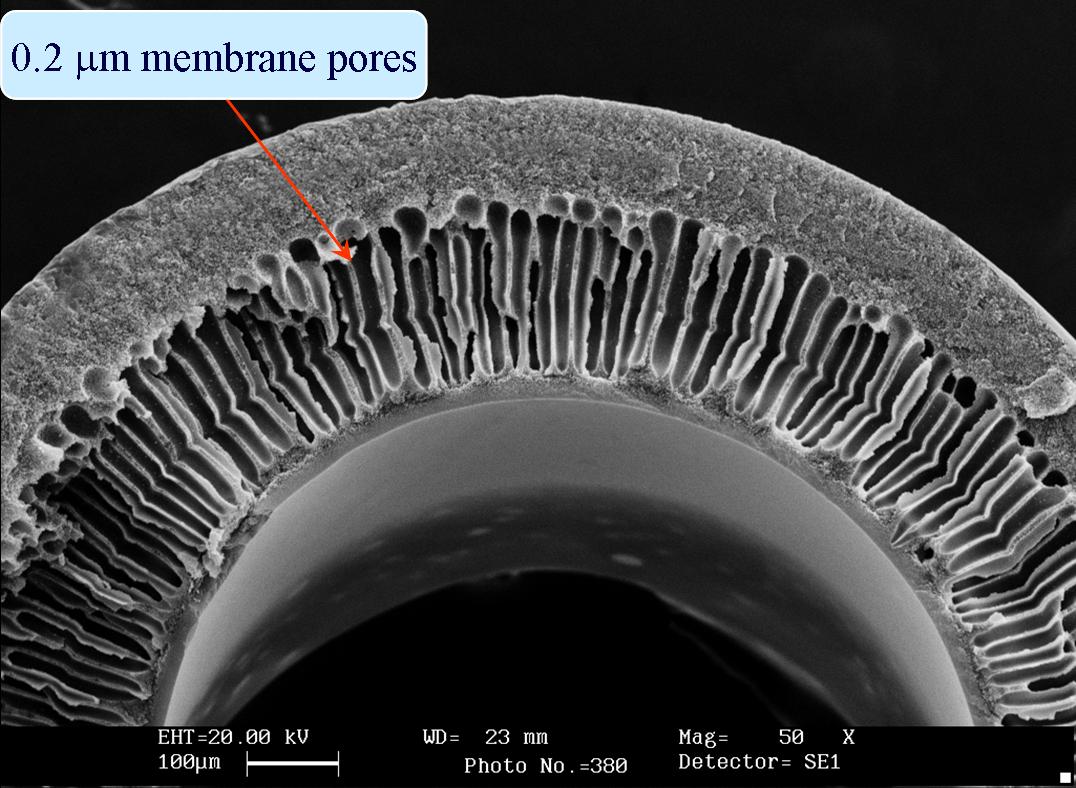

1.

MF/UF Membrane and RO Membrane for Water Reclamation

|

| |

|

|

| |

|

Click Here for

More Membrane Water Research

Stabilization/Recrystallization for Waste

Reutilization |

|

|

|

1.

Pre-processing

Marine Clay for Direct Land Reclamation

(December 2011)

This project is to use

chemical additive to treat marine clay for direct land

reclamation application. The objective is to

improve the consideration performance of marine clay. This

project is supported by MPA.

|

2.

Converting

Dredged and

Excavated

Marine

Clay into

Hierarchically

Structured

Land

Reclamation

Material

Using

Re-stabilization

Technology (April 2010).

This project is

to

(1) design

the matrix use the “concept of waste to treat waste”;

(2) to evaluate

the physical

and

engineering properties of the land reclamation material;

(3) design

and evaluate

the possibility of large

scale commercial application.

.

|

|

3. Converting Contaminated DredgedClay and

Industrial Wastes Into Value-added Products

Collaborators:

MPA,

Subana

and

NES

TEC Award from

Prime Minister's Office, Singapore |

The

dredged materials with heavy metal content exceeding the

levels set are mainly from rivers, shipyard and harbour

basins, and cargo terminals and have to be disposed at

current offshore dumping ground. Industrial wastes are

generated by more than 2,000 companies in Singapore and

required treatment to render them safe for ultimate disposal

at dumping ground as well. The current dumping group will be

filled by 2008. There is an urgent need to search a best

alternative solution for not only reutilizing the dredged

materials and the industrial wastes into value added

products but also preventing heavy metal leaching problem.

We had a joint project consisting MPA, Surbana, NE and NTU

to look into the problems of contaminated dredged materials

and industrial waste in Singapore at pilot scale. The joint

project was supported by TEC to conduct a pilot test to (1)

confirm the technology and process in a mass production

level, (2) to test the products for applications such as

land reclamation fill, road construction and building

projects, and (3) to estimate the operational and costing

parameters for setting up a full scale commercial plant.

The TEC project was implemented on the 15 July 2004 and

completed on 30 December 2005. |

| |

|

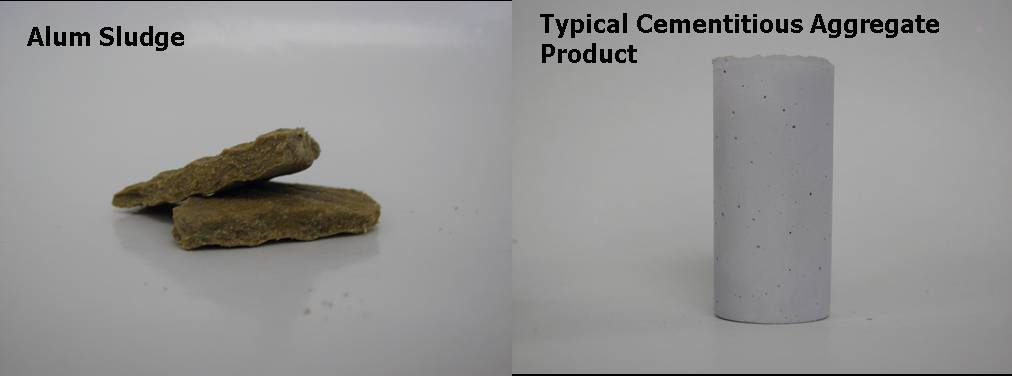

3. Converting

Sludge from Waterworks into Value-added Products Using

Frontier Recrystallization Technology

Collaborators:

Stanford University

and

PUB |

|

| |

|

4.

Reutilization of Steel-making By-product into Asphalt

Pavement Material

Collaborator: NatSteel |

|

|

|