September

1999 Article 3

MPE

INDUSTRIAL ATTACHMENT STUDENT WINS TOP PRIZE IN SEAGATE TECHNOLOGY INTERNATIONAL’S

INTERNS PROJECTS COMPETITION

|

|

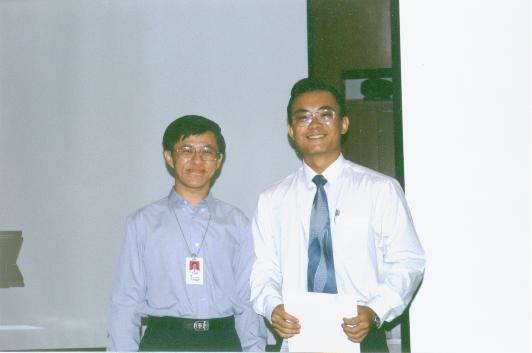

Wilson

Oh (MPE) (on the right), First Place Winner with Mr T H Chee, Vice President,

Drive Engineering Asia Pacific, Seagate Technology International

|

This

year Seagate Technology International started a project competition to

foster creativity among their interns from both NTU and NUS. They

also wanted to encourage the students to learn presentation skills, etc.

More importantly, through this program, they wanted to identify good potential

employees.

A

total of 69 interns from both NTU and NUS, attached to the various plants

took part. The competition involved 3 rounds. The first round

was on an Intra-plant level, the second round, on an Inter-plant level,

and the top five qualifiers presented their projects at the Finals.

The panel of judges comprised academics from NTU and NUS and also Directors

from the various plants. Mr Wilson Oh walked away with the Top Prize

of $500. He had undergone the School’s Leadership Development Program

which was introduced to identify and develop potential leaders among the

“cream of the crop.”

Mr

Oh was attached to Seagate Technology International Customer Service Operations

(CSO), from 11 January to 26 June this year, as part of the School’s Third

Year Industrial Attachment program. During his stint with CSO, he

was assigned to the Department of Industrial Engineering and Strategic

Planning. He handled many projects, ranging from process improvements

to plant layout. However, throughout the period of attachment, he

had the challenging task of identifying and investigating the problems

with the plant operations. This was indeed a mega-scale project.

Having

carefully identified and performed a thorough investigation, Mr Oh developed

a new system for the plant operations. This involved the flow of

materials, as well as the merging of some of the functional areas.

The advantages of the new system include a reduction in the level of inventory,

improvements in the cycle time, and better management of Work-In-Progress

(WIP). All these contribute towards making the factory more “lean”,

in line with the organizations drive towards “Lean Manufacturing”

A

presentation was made to the top management and the new system was accepted

and implemented in various phases. The initial phase of implementation

saw a substantial decrease in the level of excess inventory.

Subsequent implementations are currently in the pipeline, and with such

promising results, this new system may very well be implemented in other

Seagate plants with similar operations.

|

|