THERMOELECTRIC MATERIALS

|

Thermoelectric (TE) materials have promising applications in power generation and cooling because they can directly convert heat energy into electricity or vice versa. By recovering the large amount of waste heat from power plant and engine exhaust, TE devices may provide us a better way to alleviate the oncoming energy crisis/shortage. However, to achieve the full potential of this technology, the next generation TE materials are needed in order to develop higher performance and lighter weight TE devices. Another application of TE materials and devices lies within their use as Peltier elements for cooling purposes such as for active cooling of electronic printed-integrated circuits. |

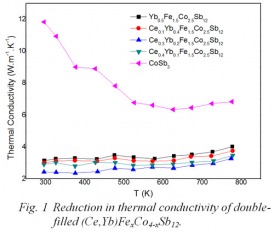

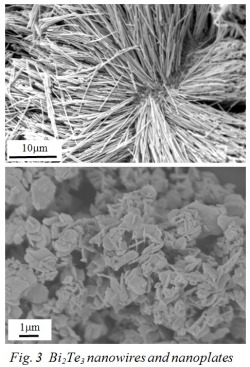

Our work here focuses on the development of low temperature (up to 400K) Bi2Te3-type for cooling applications and intermediate temperature (400-800K) CoSb3 skutterudites-type TE materials for power generation application. Our approaches to improve the performance of TE materials are:

• By preparing phonon glass and electron conductor (PGEC) TE materials through substitutional & impurity doping.

• By further reducing the thermal conductivity through extra phonon scattering approaches:

- introducing more than one filler atoms in the voids in skutterudites

- incorporating nanostructured materials into a bulk matrix of similar materials to provide nanoscale phonon scattering centers

• By fabricating low dimensional nanostructured TE materials such as thin film and nanowires, where high TE performance can be achieved by quantum confinement effect.