ENERGETIC MATERIALS

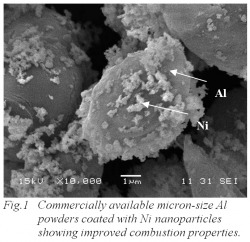

Aluminum has been widely used as a high-energetic material in areas such as propellants due to its high enthalpy (31kJ/g compared to coal of 16.2kJ/g). There has been an increased research effort toward use of nano-aluminum. However, practical uses are limited due to its slow ignition time that is contributed by the formation of the protective oxide layer, alumina on the particle surface. Aluminum typically ignites in oxidizing atmosphere only after heating up to temperatures close to the melting point of alumina, 2300K.

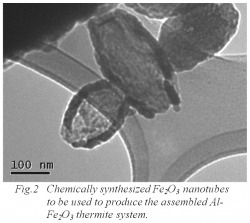

Our research focuses on Al-based thermite systems to optimize the thermal properties of aluminum. The energy released in redox reactions of thermites depends on the arrangement of oxidizer and fuel molecules. In many cases, this reaction is a solid-state diffusion driven process depending mainly on the interfacial contact area between the oxidizer and the fuel. An increase in the interfacial area, results in an enhanced rate of energy release. Our approach will be to homogenize the distribution of the fuel particles around the oxidizer molecules. This can be achieved by molecular level self assembly processes wherein fuel nanoparticles are arranged in an orderly and controlled manner around oxidizers or vice versa. Furthermore, design of energetic nanocomposites, such as a templated thermite-polymer composite, will also be a novel approach to combine both structural and combustion properties in the materials.