|

|

Bioprinting and Biocompatible

Materials

Re-defining a New Era of

Applications With 3D Printing

|

|

|

By National Additive

Manufacturing Innovation Cluster featuring:

-

Dr

Lim Yujing, CEO & CTO, Osteopore,

PhD (BioEngineering, NTU)

-

Mr Linhan

Wu, Principal (Education and Community), Hyperganic,

Bachelor (Communications and Information, NTU)

-

Mr Lim Woon Yong,

Research Engineer, AM.NUS, Bachelor (Engineering, NTU)

|

Dear Students,

Advances

in 3D printing techniques and materials research have enabled physicians, clinicians,

surgeons, and scientists to develop new treatment strategies and medical

devices for biomedical applications. These advancements in 3D printing have

introduced us to a new branch of medical therapy, Regenerative Medicine.

In

this edition, we are focusing on Bioprinting and Biocompatible materials.

Bioprinting technologies and biocompatible materials have enabled researchers

and clinicians to develop biocompatible implants, scaffolds, organoids,

prosthetics for biomedical applications. Let us explore the latest

developments from promising Singapore-based MedTech enterprises that are

redefining a new era of Regenerative Medicine and Tissue Engineering.

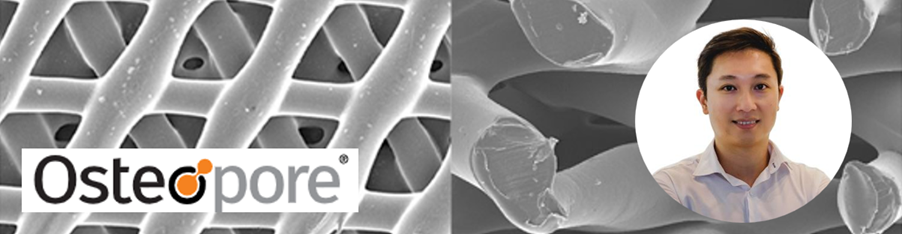

Osteopore (ASX: OSX)

A Global Leader in Regenerative

Medicine Solutions

Integrating

the science of Tissue

Engineering and Regenerative Medicine with 3D printing technologies to

design, develop and manufacture implantable devices Osteopore

(ASX: OSX) is a Singapore-based medical technology enterprise specialising in

providing Regenerative Solutions for biomedical applications.

Helmed

by Dr Lim Yujing, CEO & CTO, Osteopore (PhD. NTU) and his team, Dr Lim will share

how he got started on this journey of running a medical technology

corporation.

|

The

implant market of the medical device industry is vibrant, dynamic, and

driven by a constant influx of surgical innovations designed to augment

clinical outcomes and patient experience.

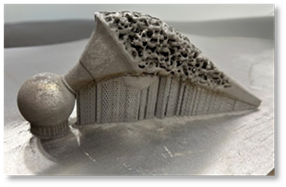

Osteopore is a pioneer

in the area of regenerative bone healing by 3D microstructures. Our deep

understanding of how bone heals have enabled us to design, 3D print, and commercialise bioresorbable bone implants

that make a difference in clinical outcomes and patient experience.

With

the support of specialist surgeons working in craniofacial reconstruction

and augmentation, Osteopore has achieved more

than 100,000 implants in patients, demonstrating safety and

effectiveness for more than 15 years.

|

As

we continue to grow, we strengthen our understanding and develop solutions

for other tissue reconstruction needs such as cartilage and tendon.

In

addition, we continue to expand our clinical applications beyond the craniofacial; going into rhinoplasty, dental, and

orthopaedics. Working in this exciting field requires a broad-based

understanding from several academic disciplines, including engineering, the

sciences, and medicine. While classroom learning provides a foundational

knowledge, continuous experiential learning through research,

experimentation, commercialisation is equally important.

Gaining

experience through internships and part-time jobs is highly beneficial.

Additionally, opportunities to work with research groups focused on tissue

regeneration should be considered.

|

In

research, it is important to identify clinical needs to guide the

development of appropriate solutions this can often be achieved by

working with specialist surgeons who can better identify and describe the

clinical challenges that they face. We look forward to the next innovation!

Author: Dr Lim Yujing, CEO & CTO of Osteopore (ASX: OSX). Dr Lim holds a Masters

of Engineering from NUS and PhD (Bioengineering) from NTU. He has

more than 10 years of research experience in Tissue Engineering and

published extensively in internationally peer-reviewed journals.

Photos sources: https://www.osteopore.com/

https://www.linkedin.com/in/yujing-lim-19b40046/

|

|

|

|

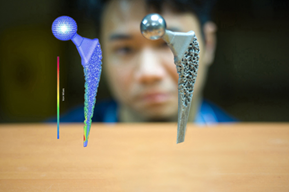

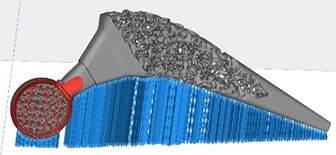

Revolutionising

Hip Joint Implants with Advanced Lattice Design for Optimal

Osseointegration and Weight Reduction

|

|

|

By Linhan Wu,

Principal, (Education and Community), Hyperganic;

Bachelor of Communications and Information (NTU)

|

|

|

|

|

|

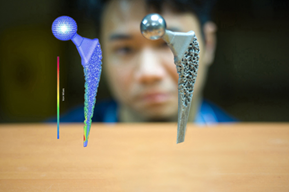

The

Challenge: The primary challenge in hip implant

design is optimising structural integrity and weight to improve both

longevity and comfort for the patient, while also ensuring rapid

osseointegration. Conventional design workflows are not only time-consuming

but also limited in their ability to iterate quickly and explore a wide

range of design configurations.

Our

Approach: Leveraging Hyperganic

Core, our team employed a novel approach that integrates quasi-meshless

simulation with algorithmic engineering. This method allows for the

automatic generation and evaluation of complex lattice structures within

the implant. We adopted a Grow-as-you-go workflow, which utilises a

feedback loop to refine the implant design iteratively based on simulated

performance data.

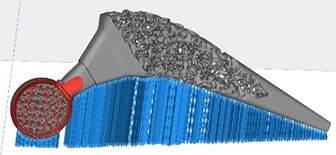

Stochastic

Lattice Optimisation: The stem of the hip joint implant was

designed using a stochastic lattice structure. The algorithm calculated

optimal beam thickness by simulating the stresses the implant would

experience under typical loading conditions. This ensured the implant was

strong where necessary but not excessively heavy.

|

Topology

Optimisation: The design process incorporated

advanced topology optimisation to minimise material use, while maintaining

essential structural properties. This approach adjusted the density and

orientation of the lattice beams dynamically, aligning the material

distribution closely with stress distribution patterns.

Solution:

The integration of Hyperganic

Core's capabilities transformed the design process.

Performance-driven

Design Iteration: Each design iteration was informed by

previous simulation results, allowing the implant to evolve towards an

optimal structure. This method reflects natural evolutionary processes,

where iterative trials refine biological structures for improved performance.

Reduced

Design Time: The new workflow significantly cut

down the design cycle time. What traditionally took months in iterative

testing and redesign could now be accomplished in weeks, with each

iteration taking place in a fraction of the time required by traditional

methods.

|

Enhanced

Implant Performance: The final implant design achieved a

balance of reduced weight and increased durability. The optimised lattice

structure provided superior load-bearing capabilities and improved

integration with bone tissue, promising a higher success rate in clinical

applications.

Conclusion:

The application of Hyperganic

Cores algorithmic design and quasi-meshless simulation marked a

significant advancement in the field of medical implants. This case study

not only demonstrates the potential for sophisticated digital tools to

enhance medical device design but also sets a new standard for the rapid

development of customised implants that better meet the needs of patients.

Author: Linhan

is Principal (Education and Community) at Hyperganic,

a German-Singapore physics-driven engineering software startup, where he

champions technical marketing, communications, and developer relations.

With experience in innovation management, deeptech

venture building, and education technology, Linhan

is a multi-disciplinary communicator who harnesses the power of business

and design to build a better tomorrow.

Source:

https://www.linkedin.com/in/wu-linhan/

|

|

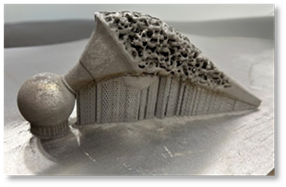

Ideation to

Reality: Development of a novel 3D printed Titanium Alloy 6-4 Hip Implant

|

|

|

By: Lim Woon Yong, Research Engineer, AM.NUS

(under guidance of Prof Sing Swee Leong, NUS)

Bachelor of Engineering (NTU)

|

Woon Yong's inspiration journey began

when he was an undergraduate in NTU School of Mechanical and Aerospace

Engineering with a simple yet profound question: How can we lighten

the part weight without compromising the mechanical properties? Fueled by

curiosity and a desire to make a meaningful impact, he set out on a path that

would lead him to the forefront of orthopedic prothesis design. Recognising the potential of additive manufacturing and

advanced materials, Woon Yong envisioned to develop an intricate hip implant

that combined strength, durability, and biocompatibility.

With years of experience in researching

the uses of titanium alloy in biomedical applications and a passion for

pushing the boundaries of medical device innovation, Prof. Sing Swee Leong

provided Woon Yong the wisdom and direction needed to navigate the complexities

of hip implant design. Under his mentorship, Woon Yong gained insights into

further development of the hip implant by using Hyperganic

simulation, Materialise Magics software, and 3D

printing as fabrication method. Titanium alloy 6-4 was chosen as the choice

material due to its desirable properties such as biocompatibility, high

corrosion resistance and high stress tolerance.

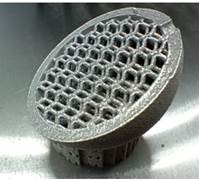

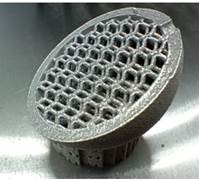

Woon

Yong redesigned the femoral head joint from solid to open lattice structure,

added a shell to convert the solid sphere to hollow structure. Materialise

Magics software was used as a final finishing touch to generate the open

lattices.

Finally,

Woon Yong printed the hip implant using Renishaw Ren500M (housed in AM.NUS) which abides by

ISO13485 medical devices standards. ISO 13485 served as Woon Yong guiding

framework, ensuring that every aspect of the project from design and

development to manufacturing and post-processing adhered to the highest

standards.

|

|

|

|

|

3D printed cross section of the sphere

(femoral head)

|

Selected sectional view of femoral head

(Materialise Magics

View)

|

Final 3D printed titanium alloy hip implant

|

|

Author:

Lim Woon Yong is currently serving as a Research Engineer in AM.NUS.

He is an alumni of NTU, holds a Bachelor of

Engineering (NTU) and obtained ASTM Professional Certificate Course in AM.

Woon Yong had 6 years of research experience in development of biomedical

devices, Additive Manufacturing, Metallurgy and Engineering Design in local

research institutions.

Source: https://www.linkedin.com/in/woon-yong-lim-984b5a158/

|

|

If you are interested in additive

manufacturing, now is an exciting time to explore a career in this dynamic

field. You too, could be part of these groundbreaking changes that impacts

patient care and technological advancements.

Follow

NAMIC on LinkedIn and visit their website for the latest industry updates.

|