|

Highlights of the week:

For more career opportunities

from various industries, please access Career Axis.

|

CAREERS IN 3D PRINTING

In demand:

Talents for Careers in 3D Printing and Advanced Manufacturing Technologies

By National Additive Manufacturing Innovation Cluster, featuring

Mr

Goh Wei Jiang (Craft Health Pte Ltd)

Mr

Amit Nanavati (Bralco Advanced Materials Pte Ltd,

Singapore)

Mr Lim Wen Yong (Applications Engineer, SLM

Solutions)

|

|

Dear

Students,

Strong national support is creating new

opportunities for deep-tech MNCs and local startups’ expansion in areas of

Advanced Manufacturing and 3D Printing.

In this issue’s edition, we explore the interesting

uses of manufacturing technologies, especially 3D printing by MNCs and local

enterprises to spearhead innovative and enterprising ideas in the

manufacturing sectors. Find out how this technology can be used by hobbyists,

creatives, architects, industrial engineers, biologists, and other

professionals in contributing to economic growth.

SPOTLIGHT: AM Talents – Mr Lim Wen

Yong (Mechanical Engineering, NTU Class of 2022)

|

|

Fuelled by passion, enabled by Technology

|

|

|

|

Engineering Assistant >>

Project Officer >> Application Engineer

Passionate

about Additive Manufacturing (AM) Technologies, Wen Yong started his

tertiary education in Biomedical Engineering at Nanyang Polytechnic. During

his semester project, he was assigned to design a tractable surgical

scalpel. Other interesting projects by Wen Yong includes designing and

developing a smart cane for National Museum Singapore, and a robotic

e-guide dog for Guide Dog Singapore. Both projects were aimed to improve

quality of life for the visually impaired.

Through hard work and perseverance, Wen Yong made it to the Director’s List

in his final year Diploma in Biomedical Engineering and went on to obtain a

Bachelor in Mechanical Engineering at NTU by

juggling work and studies part-time. Over the course of his studies, Wen

Yong started to specialise in design and fabrication of biomedical devices,

and for his final year project at NTU, Wen Yong specialised in polymer AM

applications.

Set out to deepen his practical training in Additive Manufacturing, Wen

Yong took up internships at Becton Dickerson before his full-time roles as

Engineering Assistant at NUH and Project Officer at Nanyang

Polytechnic. While at NYP, Wen Yong had the opportunity to explore

mechanical design and prototypes development in various AM projects.

When

SLM Solutions Singapore was expanding the Applications Engineering Team in

metals printing, Wen Yong took up the opportunity to further develop his

skills and experience in bridging the gaps from FDM polymer process to LPBF

metal process.

Content source and photo courtesy of Mr Lim Wen Yong

|

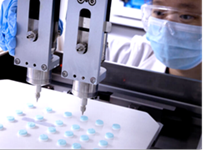

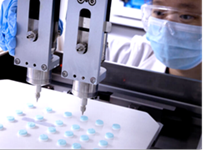

CRAFT HEALTH PTE LTD

Simplifying drug delivery and offering an end-to-end approach

from R&D to manufacturing with 3D Printing

Craft Health is Singapore’s first and only enterprise that utilises 3D Printing technologies for pharmaceuticals and

nutraceuticals. Having developed

the 3D Printing Platform for Pharmaceuticals and Nutraceuticals, Craft Health

envisions to combine the multiple active ingredients or APIs into a single

polypill, each with its own distinct controlled release profile.

|

|

|

|

|

By

developing various platforms of specialised 3D printing techniques, this

simplifies pharmaceuticals and nutraceuticals applications. It includes the

reduction of medicine intake frequency, personalised nutrition,

decentralised clinical trials, personalised medicine, and 3D printing for orphan

drugs.

|

Craft Health’s proprietary

formulations of 3D printed pharmaceuticals and

nutraceuticals includes CraftTabsTM, CraftBeadsTM, and CraftDelightsTM.

In view of their new plans, Craft

Health has recently upgraded to their new location in Science Park 1 with

latest state of the art 3D printers and laboratory facilities, in particular, a class 100k cleanroom.

|

Source:

Craft

Health

|

BRALCO ADVANCED MATERIALS PTE LTD,

SINGAPORE

Engineering functional

materials on demand

Bralco Advanced Materials Pte Ltd, Singapore is a regional technology manufacturing enterprise

with a strong focus on design, product development and manufacture of

electromagnetic components using Additive Manufacturing Technologies and

advanced materials.

|

|

|

|

|

Using

a combination of ceramic magnetic particles and polymers, Bralco’s R&D Team developed their own composite filaments

as raw materials to further 3D print customised electromagnetic (EM)

components in a wide variety of shapes and geometry (honey-comb,

spikes, slabs). These components are used as Electromagnetic

Interference (EMI) Absorbers in electronic devices.

EMI

absorbers’ main role is to prevent the electronic devices from emanating

EMI to other devices; protecting them from being affected by other

electronics nearby, particularly when the devices are becoming more

powerful and work at ultra-high frequencies.

|

Typically,

the absorbers working range falls in the range 1-40 GHz.

Use

cases include radars, antennas, sensors, 5G telecom equipment, mobile

devices, healthcare diagnostic equipment, etc, serving a wide range of

industries such as space technology, aerospace, defence, medical, consumer

electronics, electric / aviation vehicles (EV/AV) and many more.

In addition to Bralco’s

in-house material development capabilities, Bralco’s

industrial scale production is supported by their own characterisation and

parts testing facilities.

|

|

|

A 3D printed

EMI absorber – showing the spiked shapes

(Photo

courtesy of Bralco Advanced Materials)

|

|

These innovations brought a revolutionary suite of

benefits to the consumers such as:

·

Single point

solution of total RF absorption for high frequency applications

·

Lightweight and

high strength carbon fiber composite materials with multifunctional

properties

·

Custom design

and short processing time.

·

Excellent shape

conformity

·

Low cost

In

line with achieving sustainability and carbon net-zero goals, components

produced using Additive Manufacturing process has an overall material

wastage of below 1%, as versus 20% material wastage in a traditional

composite manufacturing process.

|

A uniquely designed

Faraday’s cage – an EM shielding concept applied to world of design.

Photo Courtesy: Wired

Source:

Bralco Advanced Materials

|

|

|

|

|

NAMIC’s e-job portal, AM Careers@SG

First set up in 2021, AM Careers@SG

e-job portal is Asia Pacific’s 1st dedicated Additive

Manufacturing e-job platform to address the gaps in talent management and

manpower building for the industry.

The portal regularly reaches out to industry experts

via networking events, recruitment talks, and manpower management events. We hope to address the gaps

and challenges of recruiters and talents in engaging and connecting our

diverse talent pool with the AM industry.

Do

check our new openings at https://namic.sg/namic-jobs/

|