|

Highlights of the week:

For more career

opportunities from various industries, please access Career Axis.

|

Driving

efforts in Sustainability through 3D Printing

By National

Additive Manufacturing Innovation Cluster, featuring

Assoc.

Prof Javier G. Fernandez (Chitonous/SUTD)

Assoc

Prof Carlos Banon (AirLab/SUTD)

ChopValue

Singapore

Molyworks

Singapore

Reify3D

/ Fillamentum / Philips / Fishy Filaments

|

|

Dear

Students,

Have you ever wondered how our

manufacturing sectors can drive efforts in Sustainability? In line with the UN

The Sustainable Development Goals, Singapore’s Manufacturing sector is

accelerating efforts in Sustainability through 3D Printing. Have you ever wondered how our

manufacturing sectors can drive efforts in Sustainability? In line with the UN

The Sustainable Development Goals, Singapore’s Manufacturing sector is

accelerating efforts in Sustainability through 3D Printing.

Let us look at these initiatives led by the partners

of National Additive Manufacturing Innovation Cluster (NAMIC) in using

3D Printing to drive efforts in Sustainability!

|

Hydra – The World’s Largest fully biodegradable object ever printed by Chitonous / SUTD

|

|

Prof Javier and Hydra

installation at SUTD Library

|

Inspired

by the wonders of nature, A/Prof Javier’s Fernandez Team at Chitonous

(SUTD) made use of nature’s most abundant biomaterials, Chitin and Cellulose to develop FLAM 3D,

the leading technology to 3D print the world’s tallest 3D-printed

structure, Hydra. By developing the FLAM (Fungus Like Adhesive

Materials), Chitonous enabled manufacturers to fill the missing piece in

the circular economy, enabling the production, fabrication, and degradation

of materials and products in closed urban environments. https://www.chitonous.com/

[Source: https://3dprint.com/258923/exclusive-interview-chitonous-hopes-to-use-ubiquitous-biological-polymers-for-manufacturing/]

|

|

Infusing Design, Creativity with 3D printing technologies by

Prof Carlos Banon (AirLab / SUTD)

|

|

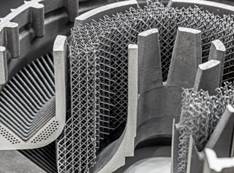

AirMesh – both

a meeting space and a lighted sculpture

|

AirMesh, an award-winning structure 3D

printed using stainless steel was installed in Gardens by the Bay. By

infusing design principles with innovating technologies, AirMesh was the first 3D printed structure in Singapore

by Prof Carlos Banon’s Architectural Intelligence Research Lab (AirLab),

producing an excellent architecture of aesthetic and functional value.

This project was one of the first collaborative projects between Building

& Construction Authority (BCA) and AirLab to realise the

vision of 3D printed architectures in Singapore.

[Source:

https://de51gn.com/prof-carlos-banon-on-why-singapore-is-at-the-forefront-of-3d-printing-and-other-innovative-tech-in-the-built-environment/]

|

|

Sustainable practices to minimise the

carbon footprint on the Environment by ChopValue Singapore

|

|

A

functional cutting board made from recycled wooden chopsticks

|

Fancy

sitting on a chair or using a study table made of used

wooden chopsticks? ChopValue Singapore has started up an island wide

business franchise recycling programme to collect used chopsticks and

reengineer them into beautiful furniture and consumer products.

Do

visit ChopValue at their site to see how their efforts  reduce the impact of carbon footprint! reduce the impact of carbon footprint!

[Source:

https://chopvalue.com.sg/pages/our-story]

|

|

Changing the way the world supplies by

eliminating the reliance on traditional supply chains – Molyworks upcycling

scrap metals

|

|

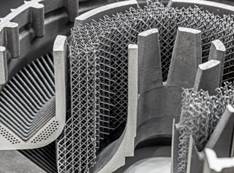

A

prototype printed from the high quality recycled

metal powders

|

Having developed the proprietary ‘The

Greyhound’ Metal Recycling System, Molyworks converts scrap

metals into high quality metal powders for Industrial uses.

Being the most flexible system on Earth, Molyworks

is harnessing The Greyhound’s powerful functionalities to change the way

the world supplies by accelerating sustainability and circular economics

around the world.

[Source: https://www.molyworks.co/]

|

|